Reverse osmosis: how does a marine watermaker work

Sea water desalination is a matter that sailors around the world had always been trying to handle over the centuries. Many different solutions had been proposed: from water boiling – in order to separate it from the salt – to the first rudimental desalinators. Just in the recent past (more precisely in 1953), it has been possible to discover a ground-breaking technology that allowed a more efficient desalination process and watermaker functioning. The technology we are talking about is the reverse osmosis.

The osmosis, a natural phenomenon that occurred in many living organisms, is a process by which a solvent (just like water) passes through a semipermeable membrane. The membrane doesn’t allow the passage of the solute (like the salt, for example). In nature this process happens in order to balance two solvents with a different salinity. In fact, during the osmosis, an amount of the solvent with a lower solute concentration combines with the solvent with a higher salinity. By this way, the concentration of the two solvents will be almost the same.

Reverse osmosis is the other way round artificial phenomenon.

Reverse osmosis | Watermaker functioning

Marine watermakers and reverse osmosis

Thanks to a high pressure, in the reverse osmosis the solvent with the higher solute concentration is pushed against a semipermeable membrane. At the same time, the membrane doesn’t allow the solute to pass, separating it from the solvent. So, the result is no more two solvents with the same solute concentration. On the opposite, there will be two solvents totally unbalanced in the contained solute.

In marine watermakers, the solvent is the water and the solute is the salt. Through the reverse osmosis and the osmosis membranes, the salt is separated from the water, making it completely mineral salts free. Moreover, the osmosis membranes also manage to restrain all the micro-particles contained into the water – as bacteria and plastics. In this way the water becomes drinkable.

In order to make the reverse osmosis efficient, there is the need of high-pressure (usually about 800 psi). In marine watermakers, this result is reached by using high-pressure pumps. However, these pumps have some disadvantages: they need a lot of power, they are very noisy and they produce a lot of vibrations.

Low-pressure pumps for the reverse osmosis: the ERS

In order to solve the problem of the energy consumption (one of the most important elements on a boat), Schenker Watermakers has created a patented and innovative system: the Energy Recovery System.

The ERS manages to boost the push generated by low-pressure pumps. This means that the reverse osmosis becomes possible even without the high-pressure pumps. In this way, the energy efficiency of the watermaker significantly improves. In fact, the energy consumption of a Schenker watermaker is only of 4 Watt per litre (80% lower than a traditional watermaker).

Moreover, because of the lack of high-pressure pumps, Schenker watermakers are really quiet and vibration-free.

The Energy Recovery System is a device integrated in every Schenker watermaker.

How does a marine watermaker work

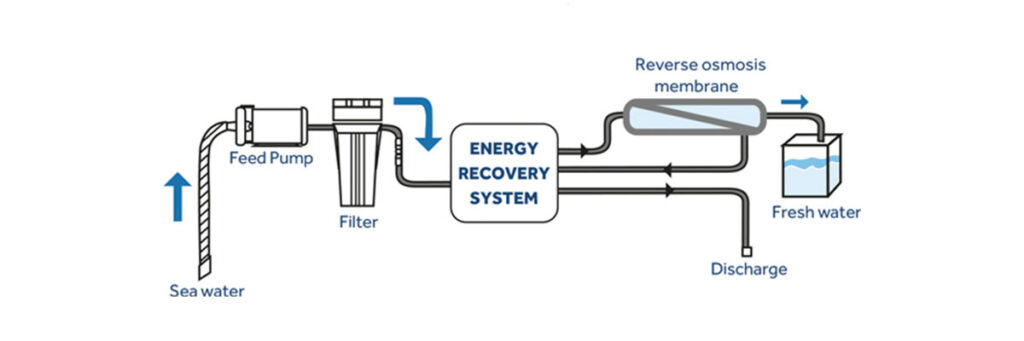

Reverse osmosis is the core of the sea water desalination process. The other steps of the process can be schematically summarized as follows (using the functioning of a Schenker watermaker as example):

- The sea water is sucked up by a feed pump.

- The filter makes the first gross prefiltration of the water, removing the bigger dirts (like sand, sediments, micro-plastics etc.) which could damage the watermaker or its osmosis membranes.

- The low-pressure pump, thanks to the help of the Energy Recovery System, pushes the sea water against the osmotic membranes at a pressure sufficient to produce the separation between fresh water and brine. The brine returns to the Energy Recovery System to transfer all the hydraulic energy to the device, and then is continuously discharged into the sea, while the fresh water is sent to the tank.

- The osmotic membranes then cause reverse osmosis to take place, separating the salt from the water and generating drinking water.

- The fresh water collected from the tank is then conveyed to the points of consumption through the on-board fresh water pump, where it can be drunk, used for the shower, for washing dishes and so on. It is always advisable to apply an additional filter on the kitchen faucet intended for the supply of drinking water.